Torsion Springs Explained and Comparing Popular System Types

Torsion springs are among the most critical – and most misunderstood – components of a residential overhead garage door system. They work in the background every time your door opens or closes, storing and releasing energy to counterbalance the door’s weight. When torsion springs wear out or break, the entire system is compromised, and operating the door can quickly become dangerous.

This guide explains what garage door torsion springs are, how they work, how they differ from extension springs, and why some systems use a single torsion spring while others rely on a dual-spring setup.

What Are Garage Door Torsion Springs?

A torsion spring is a tightly wound coil of high-tensile steel designed to store rotational (torsional) energy. On a typical residential overhead door, the torsion springs are mounted horizontally on a shaft above the top of the door opening. When the door is closed, the springs are under maximum tension; as the door opens, the springs unwind and release energy to help lift the door.

Because the average residential garage door can weigh anywhere from 130 to 300 pounds (or more for custom wood doors), manual lifting without spring assistance would be impractical and unsafe. Torsion springs act as a counterbalance, making the door feel much lighter so that a person or garage door opener can move it with relatively little effort.

Key Components of a Torsion Spring System

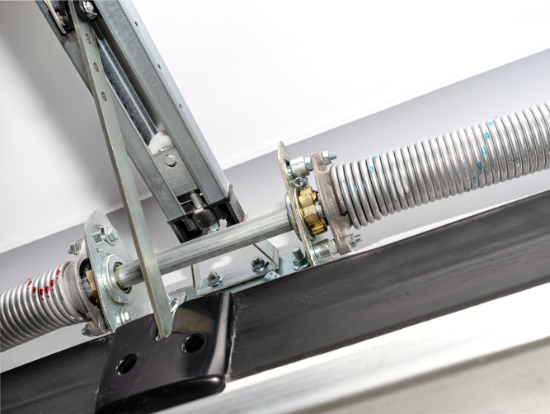

- Torsion Shaft (Tube): The steel tube or solid shaft that spans the door width and supports the springs.

- Center Bracket and Bearing: Supports the shaft and anchors the stationary center of the spring system above the door.

- Stationary Cones: Fixed to the center bracket and hold one end of each torsion spring in place.

- Winding Cones: Located at the opposite end of each spring, used by technicians to wind or unwind the springs with specialized bars.

- Cable Drums: Grooved metal drums at each end of the shaft that the lift cables wrap around as the door opens and closes.

- Lift Cables: Steel cables attached to the bottom brackets of the door, transferring the spring’s torque to raise and lower the door.

How Torsion Springs Work

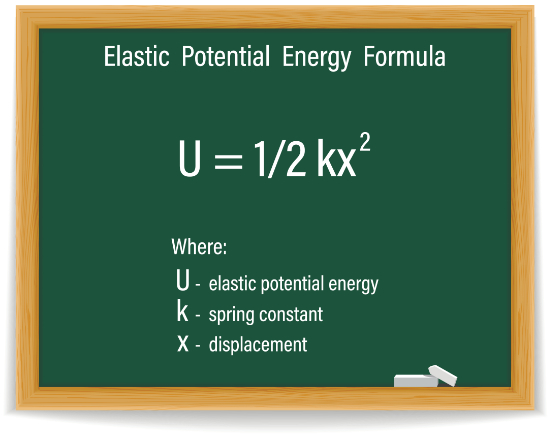

Torsion springs operate on a simple physical principle: when a spring is twisted, it stores energy; when it’s allowed to unwind, it releases that energy. On a garage door system, that torsional energy is used to offset the weight of the door.

Here’s what happens step-by-step during normal operation:

- Door Closed (Maximum Tension): When the door is fully closed, the torsion springs are wound to their designed number of turns. They are under high tension, ready to help lift the door.

- Opening the Door: As the motor or a person begins to lift the door, the cable drums rotate. The lift cables unwind from the drums, raising the door panels along the tracks. At the same time, the torsion springs begin to unwind, releasing stored energy that helps rotate the shaft and drums, effectively doing much of the lifting work.

- Door Fully Open: At the top of the travel, most of the tension has left the springs. The door’s weight is now largely supported by the horizontal tracks, and the springs are in a relatively relaxed state.

- Closing the Door: As the door descends, the drums wind the lift cables back up. The shaft rotates in the opposite direction, re-twisting (winding) the springs and restoring their stored energy until the door is closed again.

When properly sized and correctly wound, a torsion spring system makes a heavy door feel nearly weightless through its full range of motion. If the spring has lost tension (fatigue), is the wrong size for the door, or has broken, the door will feel heavy, may not stay open, or could slam shut unexpectedly.

Safety and Lifespan Considerations

Torsion springs are under significant tension and can be extremely dangerous to adjust or remove without proper tools and training. When a spring breaks, it often does so suddenly, with a loud snapping sound. Modern torsion systems generally contain the spring on the shaft, but the unexpected loss of counterbalance still creates a hazardous situation if someone attempts to operate the door.

Most residential torsion springs are rated for a certain cycle life – commonly 10,000, 20,000, or more open/close cycles. A household that uses its garage door as the primary entryway can easily reach 10,000 cycles in just a few years. Once springs reach or exceed their rated cycles, the risk of failure rises sharply.

Because of the safety risks and the need to properly match spring size, wire gauge, and length to the specific door, torsion spring replacement is almost always a job best left to a qualified garage door professional.

Torsion Springs vs. Extension Springs

Not all garage doors use torsion springs. Some older or lower-cost residential doors rely on extension springs instead. Understanding the differences can help you appreciate why many modern systems favor torsion designs.

What Are Extension Springs?

Extension springs are long, stretched springs installed parallel to the horizontal tracks on either side of the door. Instead of twisting, they work by stretching and contracting. As the door closes, the springs stretch to store energy; as the door opens, they contract to help lift the door.

Key Differences Between Torsion and Extension Springs

| Feature | Torsion Springs | Extension Springs |

|---|---|---|

| Location | Mounted on a shaft above the door opening. | Mounted along the horizontal tracks on each side of the door. |

| How They Store Energy | Store energy by twisting (torsion). | Store energy by stretching (extension). |

| Balance and Smoothness | Provide smoother, more controlled movement and better door balance. | Can cause more bounce and less precise balance if not perfectly matched. |

| Safety | Failure is typically contained on the shaft; fewer loose moving parts. | Must have safety cables to contain broken springs; otherwise, they can snap violently. |

| Space Requirements | Require headroom above the door for the shaft and springs. | Require horizontal space along each side of the door. |

| Common Usage | Standard on most newer residential and commercial overhead doors. | More common on older or entry-level residential installations. |

Overall, torsion spring systems are usually preferred because they offer better control, improved safety characteristics, and more consistent performance, especially on heavier or wider doors.

Single vs. Dual Torsion Spring Systems

Residential overhead doors can be equipped with either a single torsion spring or a pair of springs mounted on the same shaft. Both approaches are common, but they offer different performance and redundancy characteristics.

Single Torsion Spring Systems

A single torsion spring system uses one spring centered on the shaft above the door opening. The spring spans a portion of the shaft, with cable drums at each end and a center bracket supporting the assembly.

- Typical Applications: Lighter single-car doors, smaller steel doors, or budget-conscious installations.

- Advantages: Lower material cost, simpler hardware, fewer components to install.

- Drawbacks: If the spring breaks, the entire counterbalance is lost. The door often becomes too heavy to lift safely, and operating the opener can damage the motor or rails.

Dual Torsion Spring Systems

A dual torsion spring system uses two separate springs mounted on the same shaft, one on each side of the center bracket. Together, they provide the torque required to balance the door.

- Typical Applications: Heavier two-car doors, insulated doors, tall doors, or custom wood doors.

- Advantages: More even weight distribution, higher total cycle life (if properly sized), and a degree of redundancy. When one spring breaks, the remaining spring may still provide partial support, making the situation somewhat more manageable until repairs are made.

- Drawbacks: Slightly higher material and labor cost compared to a single-spring setup.

Which Is Better: Single or Dual Torsion Springs?

The best configuration depends mainly on the door’s size, weight, and intended usage:

- For smaller, lightweight doors: A properly sized single torsion spring can offer reliable service at a lower initial cost.

- For standard or heavy double-car doors: A dual torsion spring system is generally recommended for smoother operation, longer service life, and improved safety margins.

- For high-use doors (frequent cycling): Dual springs with upgraded cycle ratings can help spread the load and reduce the frequency of replacements.

Signs Your Torsion Springs May Need Service

Because torsion springs work behind the scenes, many homeowners don’t notice them until something goes wrong. Common warning signs include:

- Sudden inability of the opener to lift the door, often after a loud “bang” from the garage.

- Visible gap in the coil of a torsion spring, indicating it has snapped.

- Door feels extremely heavy or cannot be lifted manually, even with the opener disconnected.

- Door opens only a few inches and then stops or reverses.

- Door appears crooked or uneven as it moves, suggesting unbalanced tension or cable issues.

If you notice any of these symptoms, discontinue use of the door and contact a garage door professional. Continued operation with damaged or failing springs can cause further damage to the opener, tracks, or panels, and may create a serious safety hazard.

Professional Adjustment and Replacement

While it may be tempting to treat spring replacement as a DIY project, torsion springs are under enough tension to cause serious injury if they are mishandled. Professional technicians use specialized winding bars, calibrated measurements, and door balance tests to ensure that new springs are correctly sized, properly wound, and safely installed.

During a service visit, a qualified technician will typically:

- Inspect the door, tracks, rollers, hinges, and cables for wear or damage.

- Determine the correct spring size and cycle rating for the specific door.

- Safely remove the old torsion springs and hardware.

- Install and wind new springs to the proper tension.

- Balance and test the door by hand to confirm smooth, controlled operation.

- Check opener settings and safety features such as photo-eyes and force limits.

Understanding how torsion springs work and how they differ from extension and single-spring setups can help you recognize problems early and make informed decisions about repairs or upgrades. Because springs do so much of the heavy lifting behind every safe, reliable overhead garage door, keeping them properly maintained is one of the most important investments you can make in your home’s convenience and security. Give the pros at C & M Garage doors a call with any questions you might have about torsion springs or to get a broken spring replaced safely.